transparency & materials

As a future-oriented brand, sustainability is at the heart of our practice. We are very much aware of the environmental impact of our industry and commit ourselves to proving things can be done differently.

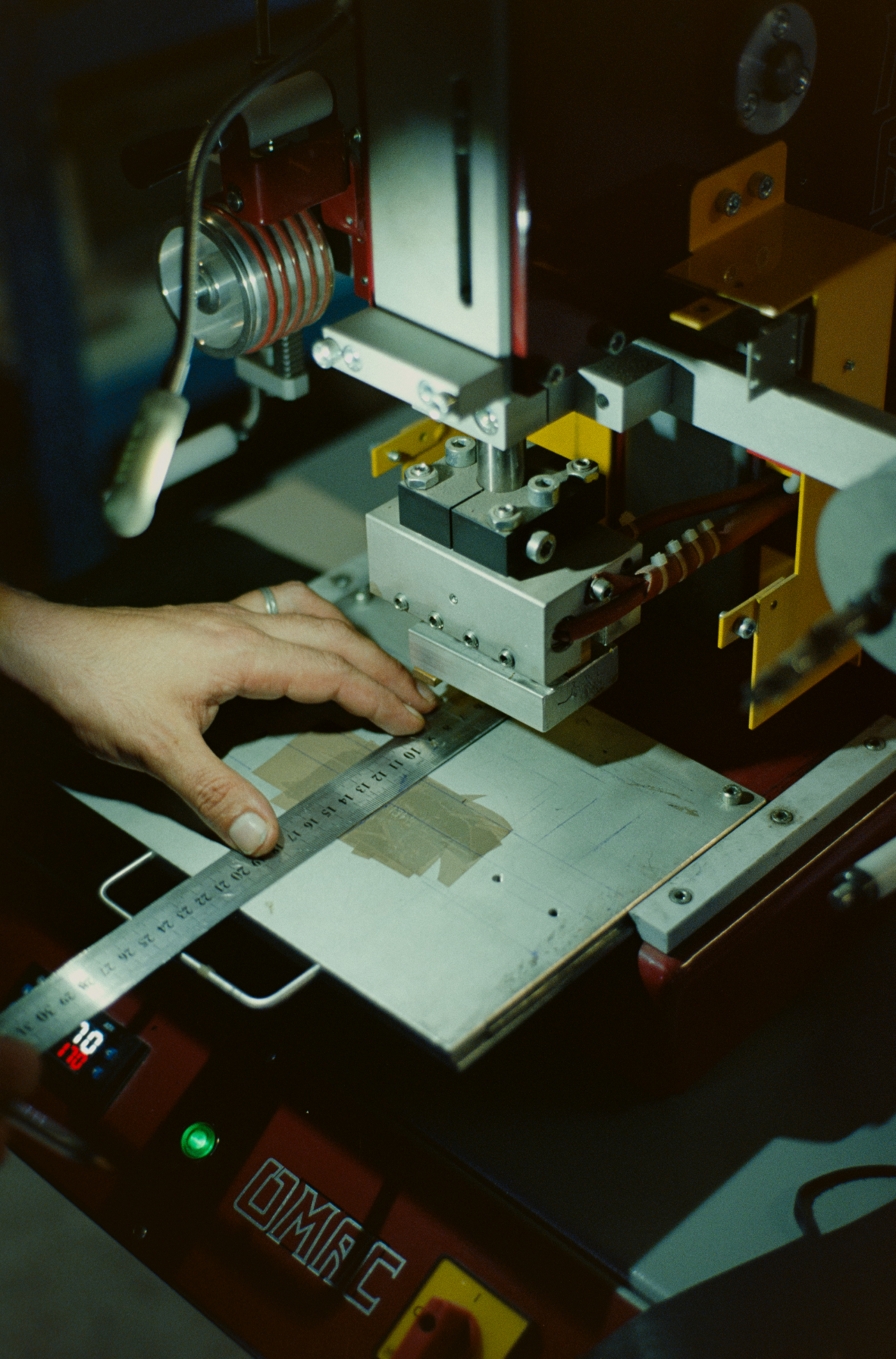

Our daily focus includes exploring circular and transparent practices, as well as researching the latest eco-friendly solutions. We maintain strong partnerships with two production ateliers, located in Italy and Tunisia.

Production ateliers

Venetian Style — Italy

Venetian Style was established in 1997 by Franco Cesarotto in the province of Padua. With a deep sense of professional pride and love for his home country, Franco named the company "Venetian Style". The brand's name is a tribute to the exceptional craftsmanship of artisans in Venice and the Veneto region.

LSP — Tunisia

LSP is a third-generation Belgian company specialising in the production of bags and accessories for high-end brands. They have an enthusiastic team of 50 people in their subsidiary in Tunisia who handle development and prototyping, as well as production. The team in Belgium manages sales, sourcing, and storage.

Tanneries

Hides are turned into leather through a tanning process. This has an environmental impact on three levels through the use of chemicals, water and energy. The tanneries we partner with use a closed-loop system in which water is reused, waste and chemicals are limited and energy is used optimally.

To minimise the impact of transport we keep our chain as short as possible. We only work with certified European leather tanneries that source their hides in Europe.

Our partners Vitelco in the Netherlands and Richard Hoffmans in Germany respectively hold a silver and golden certification from The Leather Working Group, a not-for-profit that carries out transparent eco-audits and gradually raises its standards. It continuously urges tanneries to keep improving the quality and impact of their production process.

To learn more about the Leather Working Group and their work, visit the LWG website here.

Vitelco — The Netherlands

Vitelco works with a carefully orchestrated in-house supply chain to guarantee high-quality leather. The raw materials are exclusively sourced from their own farm in the Netherlands, next to their tannery. As everything is organised in-house, there is complete transparency and traceability linked to each hide.

Richard Hoffmans — Germany

The raw materials of Richard Hoffmans are sourced in Denmark and Germany. The unique laser number printed on each hide guarantees full transparency and traceability. The number is connected to an individual animal. Richard Hoffmans process all data, such as where it was born, where it grew up, animal welfare regulations and CSR data on abattoir level.

_________________________

For our vegan collection, we work together with VEGEA and MycaNova®.

VEGEA — Italy

VEGEA is a vegan material made with the waste material of the wine industry: seeds, stems and grape skins. If you are interested in learning more about this innovative material, our good friend and sustainability expert Laurens De Meyer explains what VEGEA stands for and why it is an excellent alternative.

MycaNova® — Belgium

MycaNova® is a next-gen vegan leather made with mycelium, the root-like system of mushrooms. Until a few years ago, mycelium was considered a waste product. Today, it is dried and ground into powder which, combined with binding agents and backing materials, becomes a vegan leather alternative.

Packaging

Whether you order online or in-store, we will always wrap your bag in a cotton cover. Cotton remains the best fabric to store your bag, as it allows animal and vegan leather to breathe. In-store, we include a beach bag for you to carry your newly purchased item. For us, it is important that the packaging, in this case the beach bag, is reusable. For a trip to the city or the beach, or simply to carry your groceries.

What's next?

Our bags have been available in both animal and vegan leather since 2022. Our goal is to produce a product that will age gracefully and last a long time, providing customers with the most durable option available. We believe that each option has its own advantages and can peacefully coexist within our brand.